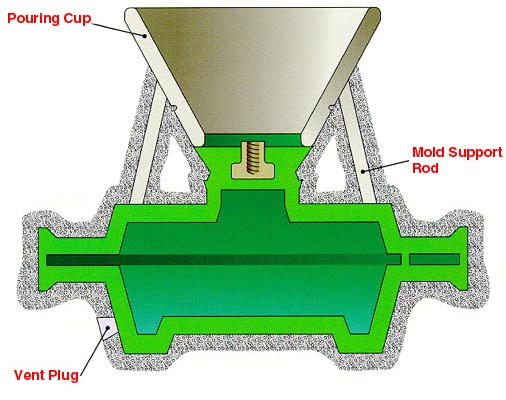

MRI® Thousand Series Investment Casting Pouring Cups

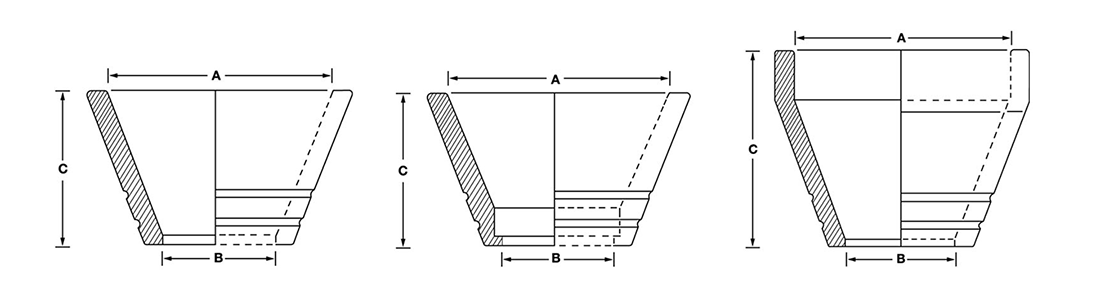

| Sizes & Shapes | Dimensions | Pack | |||

|---|---|---|---|---|---|

| Model | A (Inlet I.D.) | B (Outlet I.D.) | C (Height) | Pcs/Box | Lbs/Box |

| MRI 1790 | 5.125" (130.2mm) | 1.790" (45.5mm) | 2.340" (59.4mm) | 24 | 22 lbs. (10.0 kg) |

| MRI 2000 | 4.000" (101.6mm) | <2.000" (50.8mm) | 2.750" (69.9mm) | <48 | 38 lbs. (17.2 kg) |

| MRI 2000A | 5.000" (127.0mm) | 2.000" (50.8mm) | 3.000" (76.2mm) | 24 | 25 lbs. (11.3 kg) |

| MRI 2000F | 4.000" (101.6mm) | 2.000" (50.8mm) | 2.750" (69.9mm) | 48 | 36 lbs. (16.3 kg) |

| MRI 2000E | 4.000" (101.6mm) | 2.000" (50.8mm) | 3.750" (95.3mm) | 32 | 36 lbs.(16.3 kg) |

| MRI 2000E-F | MRI 2000E with 2.5" (63.5mm) diameter filter recess | ||||

| MRI 2375 | 4.812" (122.2mm) | 2.375" (60.3mm) | 4.000" (101.6mm) | 16 | 26 lbs. (11.8 kg) |

| MRI 3000 | 5.450" (138.4mm) | 3.000" (76.2mm) | 4.250" (108.0mm) | 28 | 50 lbs. (22.7 kg) |

| MRI 4000 | 8.400" (213.4mm) | 4.000" (101.6mm) | 5.250" (133.4mm) | 168 | 900 lbs. (408.2 kg) |

| Custom "Conical Style" Cup | Standard tolerances of +/- 2% on above dimensions apply. | ||||

| Custom "Shoe Style" Cup | Standard tolerances of +/- 2% on above dimensions apply. | ||||

Material

MRI pouring cups are produced from a high grade mullite refractory composition which has been proven in a wide variety of investment casting applications for 30 years. The MRI-engineered mullite composition features:

- High thermal shock resistance

- Smooth surface finish

- Structural stability during the pour,/

All features contribute to improving casting yields by avoiding pour cup material inclusions in the metal or alloy casted.

Quality Control

The MRI quality control program monitors dimensions, surface qualities and trace element levels. Testing and reporting of trace elements parts-per-million levels is performed by an independent laboratory. Trace element reports are provided to MRI customers, and cover iron, lead, zinc, silver, bismuth, antimony and tin levels.

Custom Design and manufacture

If a MRI Thousand Series pouring cup does not fit your need, MRI will assist in the custom design and manufacture of the specific cup required. MRI submits tooling cost, piece pricing, and drawings for review/approval before any work is initiated.

Trail Pack

So that you may inspect and test the MRI pouring cup product, a free trial pack is made available. Simply select which of the above models most closely fits your needs and notify MRI. A trial pack will be shipped for testing and approval.

MRI® Investment Casting Vent Plugs

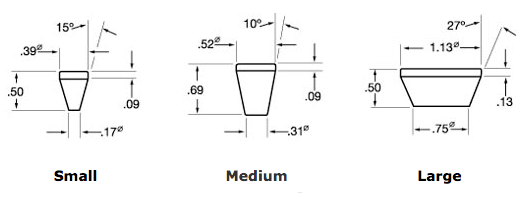

Sizes & Shapes

MRI Vent Plugs are hard ceramic products used to plug vent holes molded onto complex wax pattern assemblies which assists in the de-waxing of the mold.

MRI Vent Plugs are designed with tapered sides to prevent pushing through the vent hole into the de-waxed mold. All vent plugs have radius edges to avoid emitting ceramic inclusions to the pour.

MRI offers three standard sizes of vent plugs available without a tooling charge. Standard tolerances of +/- 1 1/2% apply.

Material

MRI vent plugs are molded of a high grade mullite refractory composition tested and proven in use in investment casting applications for over 30 years.

MRI uses only the highest quality raw materials to control trace element levels within industry standards. Testing and reporting of trace element parts-per-million levels is performed by an independent laboratory.

Custom Design and manufacture

If a standard MRI vent plug size does not fit your specific requirement, MRI will assist in the design and manufacture of a custom vent plug to meet your needs.

Trail Pack

So that you may inspect and test the MRI vent plug product, a free trial pack is made available. Simply select which vent plug size(s) most closely fits your needs and notify MRI. A trial pack will be shipped for testing and approval.

MRI® Investment Casting Mold Support Rods

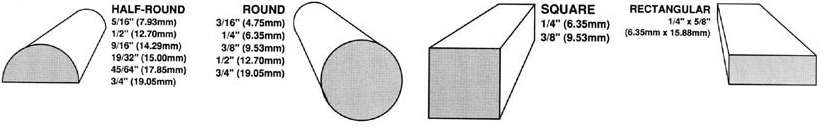

Sizes & Shapes

All shapes are available in lengths up to 12.00″ (305 mm); half-round shapes up to 24.00″ (610 mm). All edges have radius to prevent erosion during the pour.

Standard tolerances apply: .006″ camber per inch of length (.15 mm per 25.4 mm), +/- .020″ (.50 mm) on profile dimensions, +/- .010″ per inch (.25 mm per 25.4 mm) on length of rods.

When ordering specify size, shape, lengths and material needed for price quotation.

Materials

MRI mold support rods are available in two high grade refractory compositions:

- Mullite hybrid – for high mechanical strength, very good thermal shock resistance.

- Alumina – for extreme temperature exposure, very high mechanical strength and silica sensitive alloy pours.

- Both materials have been proven in a wide variety of investment casting conditions for many years.

Trace Element Control

MRI uses only the highest quality raw materials to control trace element levels within industry standards. Testing and reporting of trace element parts-per-million levels is performed by an independent laboratory.

Custom Design and manufacture

If a standard MRI mold support rod does not fit your needs, MRI will assist in the design and manufacture of the specific rod required.

Trail Pack

So that you may inspect and test the MRI mold support rods, a free trial pack is made available. Simply select which of the above models most closely fits your needs and notify MRI. A trial pack will be shipped for testing and approval.